Pashmina Introduction

Pashmina is derived from the finest wool of high mountain Capra Hircus goats. The wool is collected from the goats, once a year, without being harmed the goats in the process of shedding the wool. “Pasham”- the Pashmina Shawl finest wool known as Pashmina, lies at the bottom of course wool, comes about 5% of total wool shed from the live goats. It is the softest wool found in the living being of high snowy Himalayas. The main properties of Pashmina are it’s exotically super warmth, shine and silky texture.

There is a difference between Cashmere wool and Pashmina, as the former has normally 16-18 microns thick, whereas the thickness of Pashmina hair is only 12-14 microns. This makes a lot of difference in softness and warmthness.

Process of making Pashmina

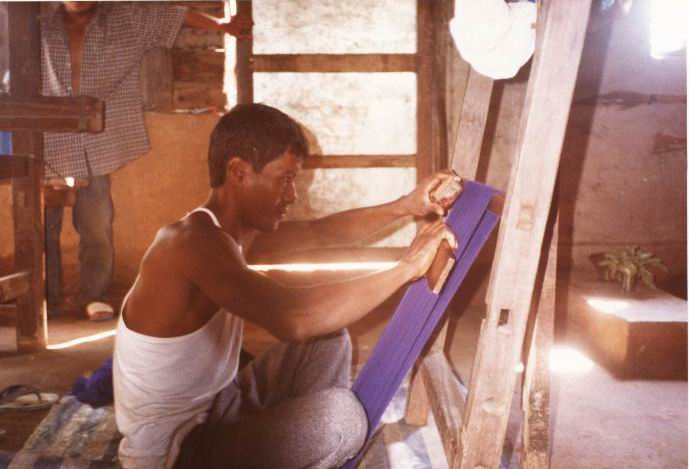

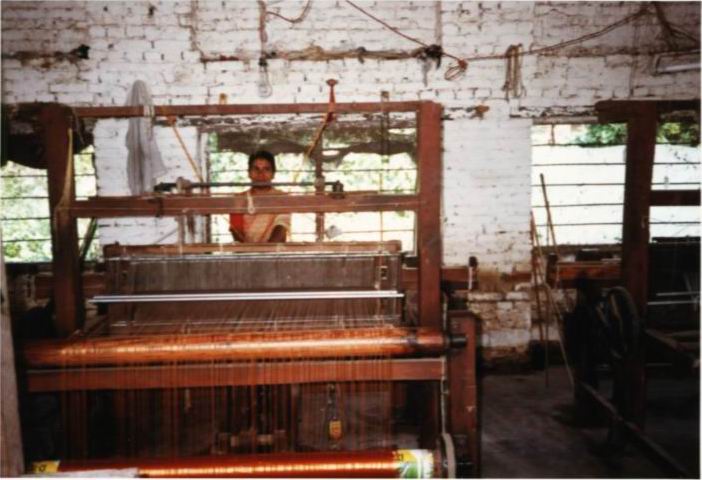

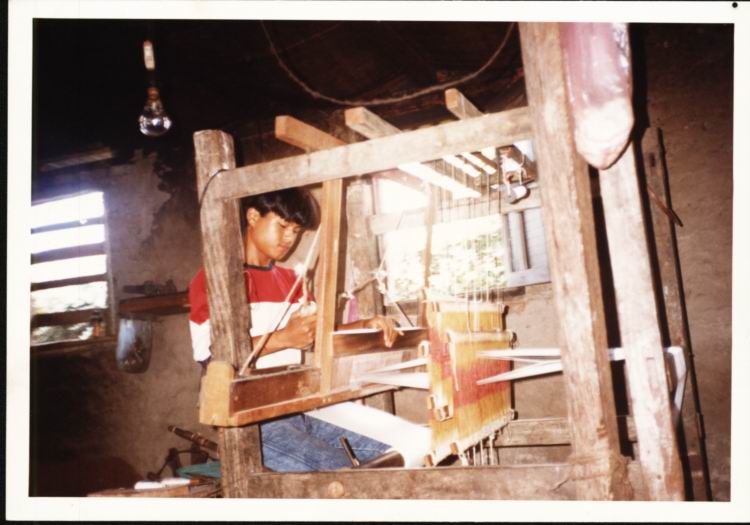

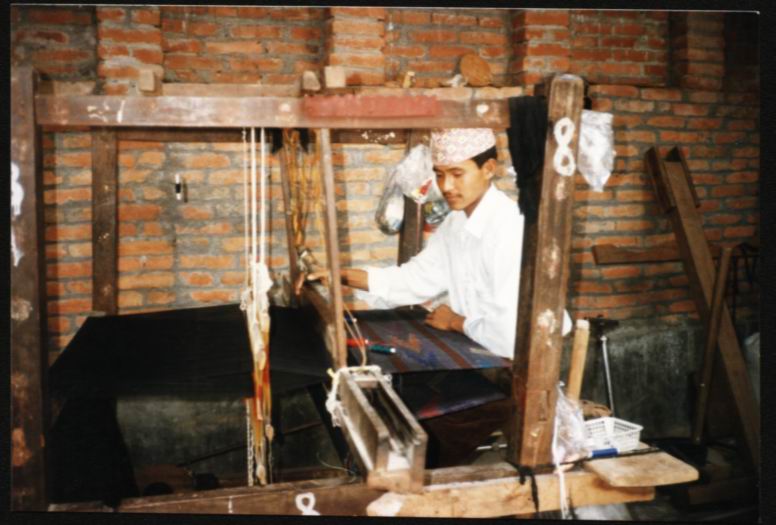

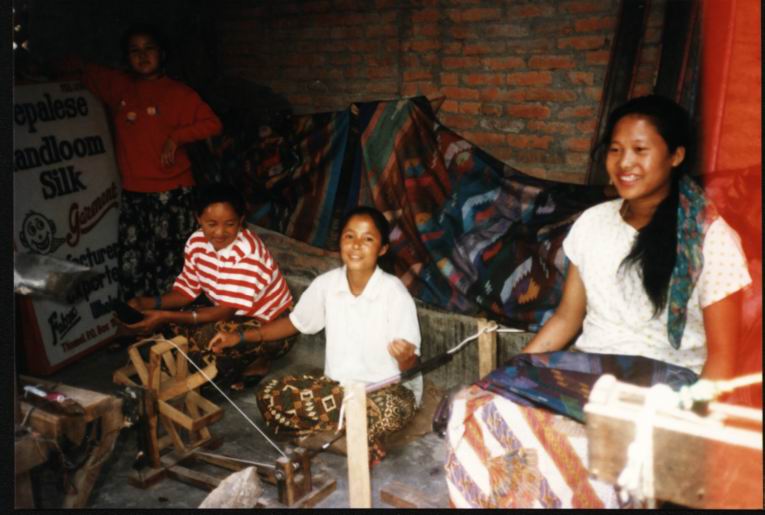

The process of making Pashmina garments (products) involves a lot of hard work. The wool produced is carded by hand and spun into very fine yarn by traditional methods using a hand-spinner. Thereafter, it is hand-woven in traditional pit looms. It takes our craftsmen about nine to ten days (spinning to finish) to weave and finish a single shawl ready for the Show room.

At present we manufacture the shawls up to 50 inches (125 cm.) width for more than 600 wide ranges of shades. Our end product can be embroidered, silk fringed or in plain design. The sizes and colors can be custom-made, provided they are in feasible quantities.

Generally, Pashmina is woven on a wrap of silk that adds strength and shine. Silk and Pashmina can be combined in any proportion, however, 80% Pashmina and 20% silk are regarded the ideal combination for strength and shine. 100% Pashmina items are also preferred by many.